THE DIFFERENCE BETWEEN SELF-TAPPING AND SELF-DRILLING SCREWS

THE DIFFERENCE BETWEEN SELF-TAPPING AND SELF-DRILLING SCREWS

In the threaded fastener industry, terms are not always consistent. The same part or functionality may have multiple names, some of which have become interchangeable, making it all the more confusing. Hence why the following question is so popular: what is the difference between self-tapping and self-drilling screws?

This is a question of functionality. However, many stores and manufacturers label screws with this description according to their own unique categorization, because different types of screws (for instance, drywall screws, wood screws, and sheet metal screws) may have one or both of these features. This guide boils the terms down to their basic definitions to help you de-code what those labels are saying.

Self-Tapping vs. Self-Drilling: The Difference

To put it as simply as possible, the biggest difference between these two types of screws is their functionality:

1.Self-tapping screws are installed into a predrilled hole, but the hole does not need to be pre-tapped with threads.

2.Self-drilling screws drill their own hole and tap their own threads.

According to this explanation, self-drilling screws are also self-tapping (because if they drill their own hole, they clearly then tap their own threads as they drill). However, self-tapping screws are not also self-drilling, because they do not drill a hole on their own.

There are certain scenarios where a self-tapping screw is used with particularly thin or soft materials and has a sharp enough point to pierce its own pilot hole, but that would be an exception to the rule.

Because these screws function differently, they also feature distinct point styles that help facilitate their specific tasks.

Point Styles

Self-tapping screws have a few different point styles based on how they shape the threads, while self-drilling screws feature unique, drill bit-shaped tips that drills the hole as the screw is driven into the material.

Self-Tapping Points

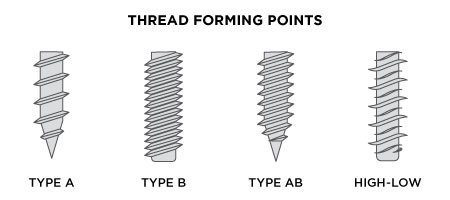

These points are available with sharp thread-forming tips, flat thread-forming tips, and flat thread-cutting tips. Thread forming and thread cutting screws are further divided into specific types.

Thread Forming: Pushes the mating material out of the way of the threads but does not remove it from the pilot hole.

1.Type A: Sharp points, course threads

2.Type AB: Sharp points, threads close together

3.Type B: Blunt point, threads close together

4.High-Low: Threads with intermittent high and low crests

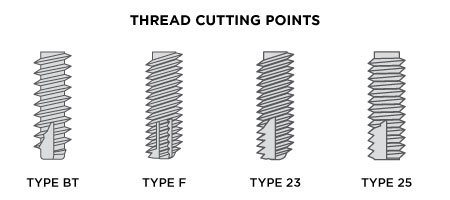

Thread Cutting: Cuts and removes the mating material out of the pilot hole.

Type BT: Blunt end with tapered cutting edge(s), course threads

Type F: Blunt end with thin vertical cutting slits, machine screw threads

Type 23: Blunt end with tapered cutting edge(s), machine screw threads

Type 25: Blunt end with thread cutting flute, machine screw threads

Self-Drilling Points

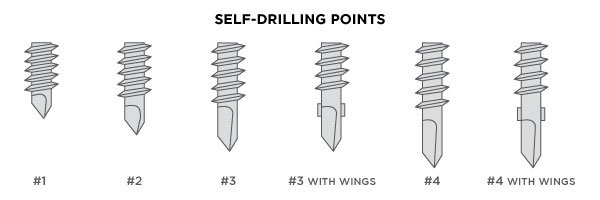

These points all feature a drill bit tip of varying lengths that dig into the mating material and drill the pilot hole. Some self-drilling screws feature wings just under the threads.

Wings: Tabs that stick out between the threads and the drill bit tip; typically used in applications that secure wood or soft material to metal. The wings (which are wider than the threads) ream the hole in the wood over-sized so the threads don’t engage with the wood and pull the board up. They break off when they contact the metal and the screw fully tightens; locking the board securely against the metal.

Drilling points are available in different point sizes, which are designated by a number that communicates how thick of material the screw can drill through, with larger numbers handling thicker material. Point sizes are available from #1 to #5.

Self-Drilling: Points that drill their own pilot holes; designated by point length and increasing ability to drill into thicker material.

#1: Able to drill through .018” - .095” material thickness

#2: Able to drill through .036” - .210” material thickness

#3: Able to drill through .036” - .210” material thickness

#4: Able to drill through .125” - .250” material thickness

#5: Able to drill through .250” - .500” material thickness

Application Uses

When it comes to choosing a screw, it is important to consider the type and strength of the application’s materials.

Self-tapping screws are often seen in applications where thin metal components need to attach to other materials like wood or metal. This includes HVAC, construction, and environments that require metal framework assemblies, like the automotive industry.

Self-drilling screws can go through different materials as well and are often used with stronger or thicker material than what a self-tapping screw could handle, although they are still considered to be used in light-gauge materials. You can find them in similar applications as tapping screws, as well as metal building and roofing settings.

For more information, visit www.primofastener.com or Email to eric@primofastener.com